Cold chain management for the pharmaceutical industry is more than just a supply chain – it’s a lifeline that many people depend on. High-value pharmaceutical commodities are critical to human health, and they require extra care and professional handling and distribution. Most pharmaceutical products are highly temperature-sensitive and require to be stored and transported in a consistent temperature-controlled environment from the manufacturers to the final customers.

As the world becomes more globalized, the distance pharmaceutical products travel from manufacturers to the end-users have also increased. This poses a greater risk to the supply chain as any small disruption could cause transport delays and increase the chance of cold chain incident.

Rise In Global Demands

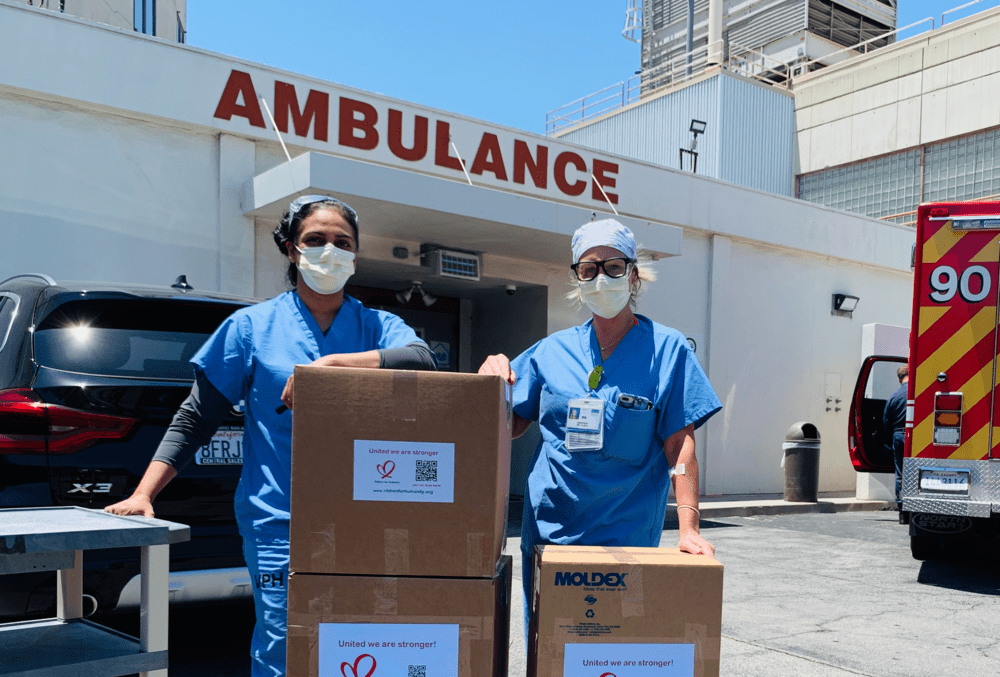

The increasing global demand for temperature-sensitive medicines and the fast-growing pharmaceutical sector has prompted urgent needs to expand cold chain logistics network capacity. The COVID-19 pandemic for example has further demonstrated how cold chain transport plays an irreplaceable role in moving critical shipments and daily necessities in localized and globalized settings.

From the urgent pharmaceutical products that doctors and patients need to the food we eat, we have never been more dependent on cold chain management to live during this challenging period.

Building a more resilient, globalized, and technologically advanced cold chain supply line has become a top priority to cope with future growths and demands. With COVID-19 vaccines transportation and distribution about to begin, the cold chain industry needs to prepare for an unprecedented challenge that is much more difficult and complex than ever before.

Many key metrics essential to measuring the cold chain’s integrity could only be monitored and tracked by highly specialized technological sensors and devices. Specialized equipment

Only equipment that are specialized have the capability to notice a small deviation of temperature or a slight change in the ambient environment. For businesses and couriers, pursuing new cutting-edge technologies could significantly improve network efficiency and protect valuable assets from damages. The investment will bring you some of the most powerful and helpful tools to empower your business to adapt to changing challenges.

Why Do We Need New Telematics Technology For Cold Chain Management?

More Reliable Features

Businesses that already own cold chain tracking and monitoring technologies may wonder why they need to upgrade to the latest and better technologies. What are some differences between the conventional cold chain solution and the smart telematics-powered cold chain package?

The traditional temperature monitoring sensors measure blower output air temperature, which gives drivers and fleet managers an inaccurate measure and false sense of the trailer’s actual temperature. There is variation in the thermal environment inside the transport trailer as the air around the door can be slightly warmer than the air around the blower.

The temperature difference between the two areas would become even greater if the door was left open for a while, and hot air from the outside is being introduced into the trailer. Thus, in this case, only measuring the blower output air temperature neglects the fact that the temperature for most of the trailer will be higher than the temperature reading sent to drivers and fleet managers.

Newer telematics-focused temperature sensors tackle this problem by measuring the actual ambient temperature of the container. Couriers can further improve the measurement accuracy by placing one tracking device at the front and one at the back of the trailer. With more equitable distributive placements, drivers and fleet managers can obtain a more accurate and precise temperature measurement representing the actual temperature at all corners of the trailer.

New devices do not just stop at measuring temperature but include new features such as tracking the trailer’s moisture and humidity level. Moisture caused by condensation can potentially damage pharmaceutical products, especially vaccines, costing businesses and couriers tens of thousands of dollars in paying customers’ compensation claims. This is a critical feature for transporting medical shipments in high-humidity regions such as Florida, United States.

An alert will be prompted to drivers and fleet managers if an abnormal humidity level has been detected in the trailer, so early action could be taken to avoid further shipment damages.

More Connected Opportunities

The conventional cold chain monitoring solution is usually made of multiple sensors that are relatively isolated and disconnected from each other. The lack of wireless transmission features made it difficult for all hardware parts to communicate with each other to create a streamlined workflow.

New telematics systems address the limitation by packing all smart sensors such as temperature monitoring, moisture and humidity monitoring, motion detection and optical sensors all into one integrated tracking device with built-in GPS, GLONASS, 2G and 4G connectivity. The high levels of integration enable new functionality such as smart analytics and a troubleshooting system.

When an alert arises, the system can quickly analyze all the collected data and readings and instantly identify which trailer’s attribute or hardware part is not performing as expected through advanced artificial intelligence algorithms. This dramatically simplifies the troubleshooting process as the system can directly tell drivers and technicians of the root cause of the problem, eliminating the need for human investigation.

Besides, the tracking device is incredibly durable and easy to install and use. The device is IP67 certified waterproof and dust resistant, as well as UV resistant. It can withstand a wide range of temperatures ranging from -30°C to +60°C, capable of handling all kinds of sophisticated cold chain tasks in any environment settings. The effortless installation process of the plug-and-play wireless tracking device means that you can have your whole fleet fully upgraded in just a matter of time without the need to pause your fleet operation or take vehicles out of services.

More Convenience

An essential work that couriers need to do after each trip is collecting and organizing temperature data logs to prepare for potential regulatory inspections. Couriers need to supply data evidence to demonstrate the cold chain integrity from end-to-end is fully protected. The conventional technologies are only capable of collecting and recording data, leaving lots of work at the end for staff to organize, manage, and create cold chain custody reports.

New telematics solutions take a different approach by combining powerful hardware pieces with convenient software platforms. The cloud-based fleet dashboard is an intuitive and user-friendly platform that summarizes all the information that fleet managers value the most in one place.

Fleet managers can track asset locations, trailer temperature log, and other vital metrics such as trailer humidity levels in real-time. All the historical data and temperature logs are automatically being sorted, prepared by the system and ready for viewing by fleet managers anytime.

There is no need to assign staff to navigate through all the complex data log files, as the system can compile cold chain custody reports for you in a matter of seconds. All the reports and data will be stored in the cloud and ready to be presented to regulatory inspections.

More Opportunities

Introducing new telematics technologies to fleets won’t only help to prepare essential teams for the unique challenges that emerged from the pharmaceutical industry but also present them with new opportunities to expand. Cold chain transport has become increasingly important in the global food chain, battery distribution, military medical supplies transport, and oil or gas industries.

In the electric vehicle sector, there is a rising need for capacity expansion and efficiency improvement of the global cold chain to facilitate the supply and transport of lithium-ion batteries. In the food chain, businesses and retailers rely on cold chain management to transport temperature-sensitive food products such as fresh seafood, raw meat, fruits and vegetables across the continent. Improving onboard fleet technologies opens up a whole new range of opportunities for your businesses, and you can be confident that you have the necessary tools to tackle a diverse range of challenges.

Building a connected ecosystem that utilizes the power of hardware and software is a fundamental objective of telematics solutions. The pandemic has drastically changed how everyone lives and how businesses run. There is nothing more important at this critical and challenging period than bringing and reuniting the world together. By adopting the latest cutting-edge technologies, we could truly maximize our logistics system’s efficiency and send the necessary goods to people who urgently needed it. In a world where travel restrictions are still in place in most countries, only through building a more resilient, stronger, and technologically advanced logistics link can we rebuild our communities back faster and better.

Contact us to speak with an industry-specific expert to see how we can elevate your businesses’ fleet to the next level and move the world forward.