As businesses begin to reopen, commercial fleets that transport fresh food products may start to feel pressure of new demand. And given the current economic environment, losing revenue due to temperature irregularities will place additional unnecessary stress on managers and drivers to ensure that shipments are never rejected. Here we will discuss the responsibilities that food transportation holds, as well as how telematics can help ensure that transporters stay true to their responsibilities.

The Financial Stress Of Transporting Temperature Sensitive Food Products

200 billion metric tons of food are transported globally each year and 35% of that is transported by land. Of the 35% of food being transported, if even one shipment in a 36 foot trailer does not meet strict temperature guidelines, businesses can lose upwards to $30, 000 if the load is rejected upon delivery. With losses costing thousands of dollars, fleets can’t risk conducting insufficient temperature monitoring practices of frozen or refrigerated goods.

How To Properly Transport Temperature Sensitive Goods

Even though there are a few ways to transport food products, many have found that there is only one way to do so with the least amount of risk. 360 telematics solutions that focus on monitoring various aspects of the commercial vehicle is one that is praised by nearly everyone.

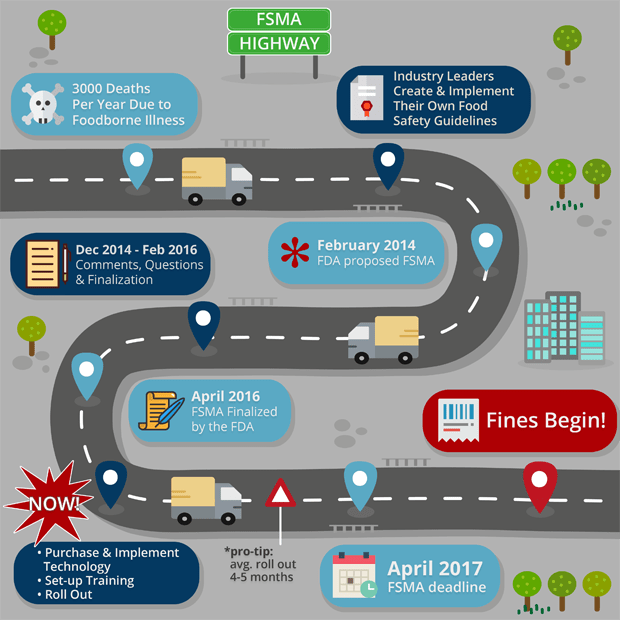

Where Temperature Compliance Comes From

To help ensure food safety, the FDA introduced the Food Safety Modernization Act (FSMA). The FSMA created a strict, standardized playbook for preventing unsafe food transportation. Regulations made it necessary for there to be proper temperature control during transportation in addition to proper documentation of human and animal food products,whether the food is in open or closed containers. While the FSMA did not mandate the use of telematics, it is clear that telematics technologiy offers a far more reliable, precise and efficient way to ensure that compliance is met. According to the FSMA, three rules must be met:

- Shippers must ensure that the vehicle performing the transport of food has been pre-cooled to the appropriate temperature prior to the goods being loaded

- Transporters must ensure that cold chain integrity was maintained for the duration of the trip, and explain any temperature breaches along the way

- A record of the last three shipments must be maintained for at least a year by the shipper/transporter

Why Some Commercial Transportation Businesses Are Struggling

Fleets often struggle to properly maintain consistent temperatures during food transportation. Part of the problem is with current tools and processes that make it difficult to identify when temperatures are starting to dip or when they have reached unsafe temperatures. The in-cab temperature display for reefers can be misleading as it only measures the blower output air temperature, not the ambient air temperature of the trailer itself which can often vary by 1-2 degrees from the front to the back. It also does not take into account the conveyor effect of cold/hot air temperature variations caused by the opening and closing of doors.

Telematics In Reefers

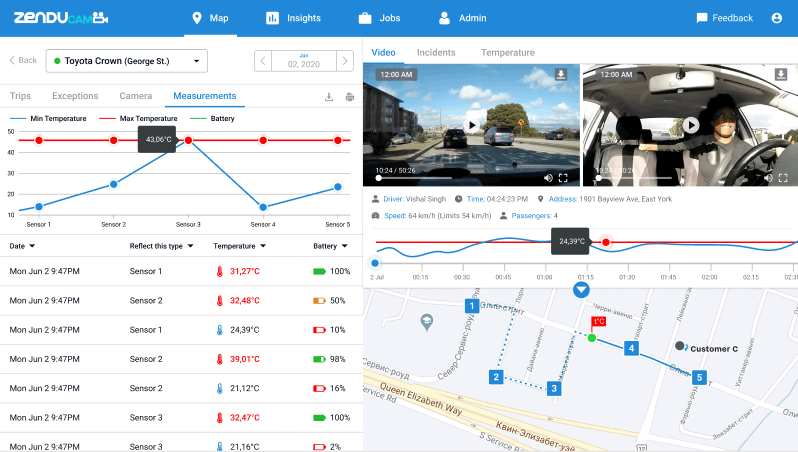

Telematics are praised by commercial food transport companies as solutions can provide real-time visibility into all the issues listed above.

Telematics Helping To Maintain Appropriate Pre Cool Temperatures

Telematics solutions are able to show what the ambient temperature is in real-time, prior to loading and even afterwards. Notifying managers and drivers when the blower is no longer distributing air at the appropriate temperature level, or is unable to reach the appropriate temperature level.

Telematics Helping To Maintain Appropriate Temperatures During A Trip

Prior to loading a trailer, the pre cooling stage requires the trailer to reach the correct ambient temperature before the goods are loaded. However, once the doors are opened and the contents are loaded, temperatures can quickly change to non compliant temperatures. In fact, within 5 minutes of filling a trailer, ambient temperatures can change up to 10 degrees – risking deliveries to be deemed non compliant before the route has even begun! While some vehicles that are travelling far distances could recoup the lost cool air as the cool air blower continues to work throughout the entire trip, when vehicles are making frequent stops to drop off supplies locally, this temperature may never reach the correct temperature. In fact, temperatures can continue to rise as doors open and close to deliver products, releasing cool air and introducing warm air.

Telematics Helping To Keep Cold Chain Custody Reports

When telematics solutions are used, digital reports are automatically created and stored. Meaning there is more reliable food transportation information collected digitally as well as more accurately. What this means is that when fleets are asked to show cold chain custody reports within a year of the delivery (as well as previous trailer reports), they are able to easily pull up the digital document. In fact, telematics even helps fleets cut back on warehouse costs as previous paper documents for each trip no longer need to be physically stored – rather they’re kept electronically in the cloud!

Food Transportation And Maintaining Compliance Without Telematics

When telematics tools are not used, reefer fleets must manually document and record various pieces of information. Not only does this include the temperature of the trailer during the pre load phase and the blower, but during their route when deliveries are made. Such record keeping can be time consuming and unreliable as it requires drivers to manually write food transportation temperature records. And as previously mentioned, cold chain custody reports must be kept for a minimum of one year and often require large warehouse spaces to store.

When fleets are moving temperature sensitive products, they can’t afford to overlook the tools they are using to complete temperature monitoring. If you’re interested to learn more about the various telematics software solutions that can help, contact us today!